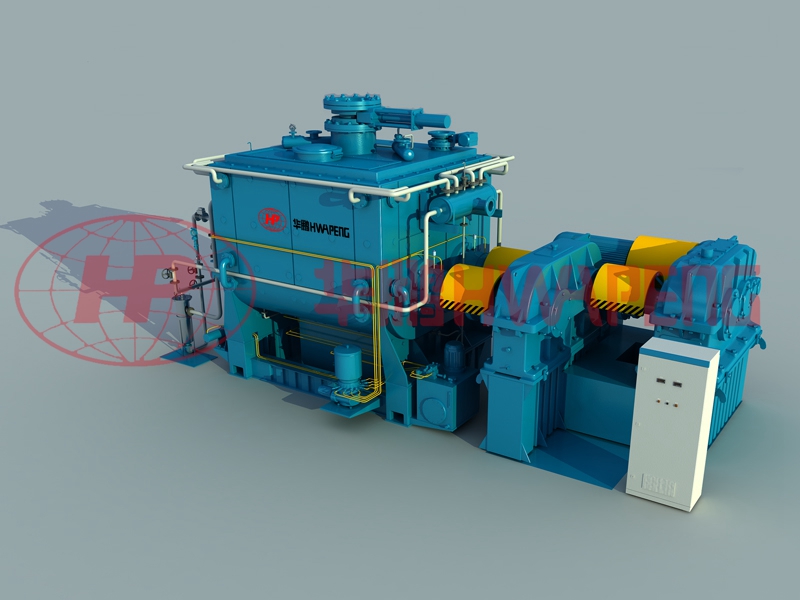

Product Description

HP-CPK series carbon paste kneaderadopts a number of patented technologies, with excellent kneading quality, good sealing performance, no dust and pitch smoke leakage.

Kneading is an important process in the production of carbon products. It mainly completes the kneading of dry materials and binder pitch, and endows paste with strong plasticity.

Under the function of kneading equipment, pitch infiltrates and merges the particle material and powder material, and wraps a uniform asphalt film on the particle surface to form the paste with good plasticity.

Inquiry Online

Inquiry Online Leave Message

Leave Message Product Catalog

Product Catalog