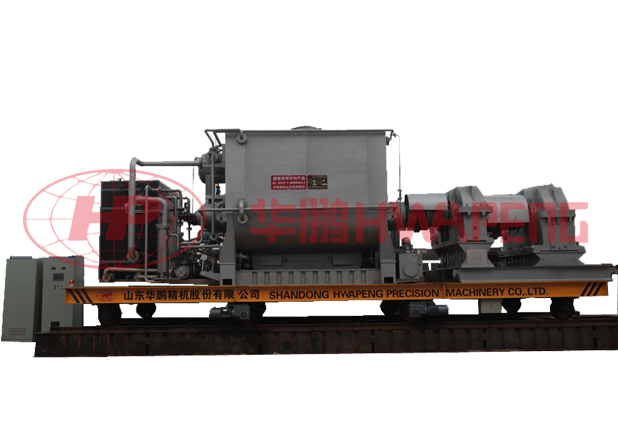

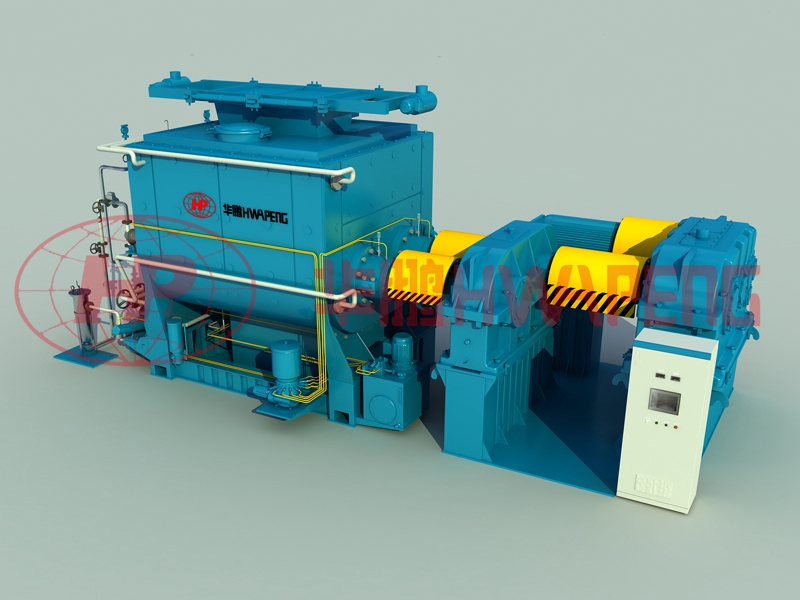

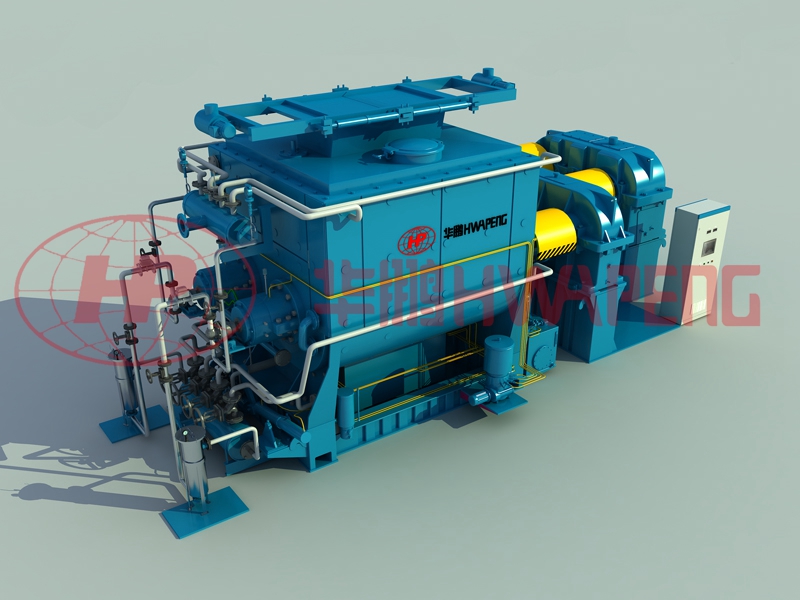

Product Description

HP-PKC Series Paste Kneading Cooler is a leading international technology product introduced and digested. It adopts low-temperature kneading technology. The material produced by kneader enters into the cooler. When the paste is cooled, it kneads the paste for the second time to further improve the kneading quality. The state of the cooling paste is divergent, no agglomeration, and the pitch smoke is completely discharged, reaching the international level of similar products.

Due to the effect of low temperature kneading, the application of HP- PKC paste kneading cooling technology can improve the bulk density of carbon products, reduce the resistivity, improve the bending or compressive strength, reduce the amount of pitch, and improve the product qualification rate.

At present, HP-PKC paste kneading cooling technology has been applied to the production of graphite electrode and prebaked anode, which has achieved remarkable results, greatly improving product quality and reducing production cost. Through the actual verification of its advantages will be more extensive in the field of carbon production.

Inquiry Online

Inquiry Online Leave Message

Leave Message Product Catalog

Product Catalog